What are the repair and modification methods for large aluminum forgings?

Views: 0 Author: Site Editor Publish Time: 2024-01-26 Origin: Site

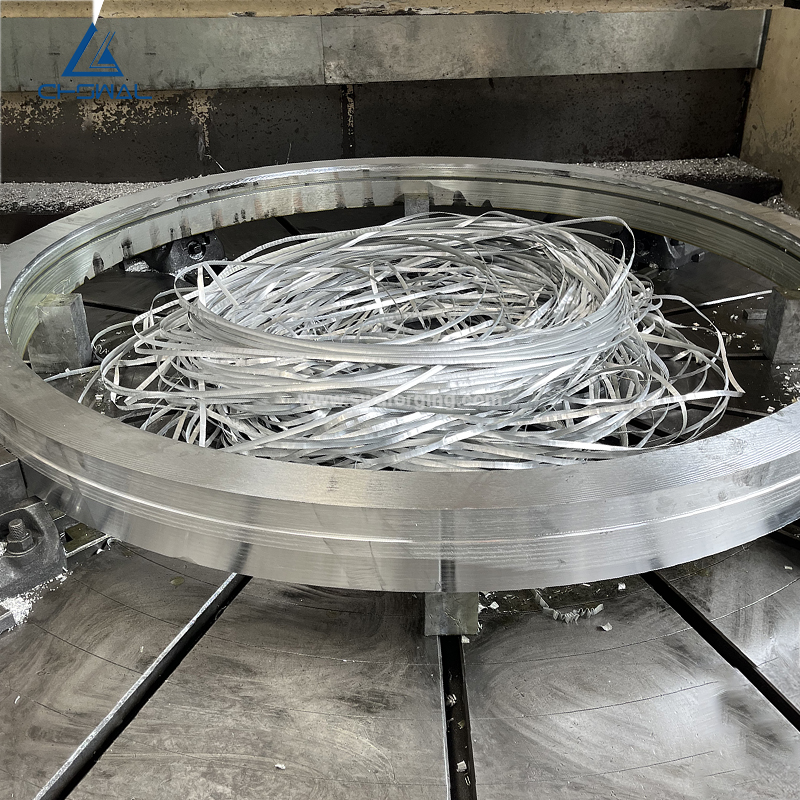

As one of the most important materials in the manufacturing industry, aluminum has numerous applications in different fields. With its excellent strength-to-weight ratio, aluminum is widely used in making large forging components that require high strength and light weight, such as aerospace and defense components, industrial machinery parts, and automotive parts. However, the manufacturing of large aluminum forgings is not always a straightforward process. Sometimes, faults and defects in aluminum forgings can happen during the production process, which will lead to quality issues. To solve these problems, various repair and modification methods have been developed in recent years. This article aims to discuss the repair and modification methods for large aluminum forgings.

Firstly, let us look at the reasons why a large aluminum forging may need to be repaired or modified. The most common causes include improper forging temperature, inadequate die filling, improper cooling rate, and material impurities. These problems can lead to defects in the part, such as cracks, porosity, inclusions, and dimensional inaccuracy. In severe cases, these defects can cause the part to fail during use, leading to safety risks and economic losses. Therefore, it is essential to identify and repair the defects in large aluminum forgings as soon as possible.

Firstly, let us look at the reasons why a large aluminum forging may need to be repaired or modified. The most common causes include improper forging temperature, inadequate die filling, improper cooling rate, and material impurities. These problems can lead to defects in the part, such as cracks, porosity, inclusions, and dimensional inaccuracy. In severe cases, these defects can cause the part to fail during use, leading to safety risks and economic losses. Therefore, it is essential to identify and repair the defects in large aluminum forgings as soon as possible.

There are several methods available for the repair of large aluminum forgings. One of the most common methods is welding. For example, if a crack is found in a forging, it can be repaired by welding the two sides of the crack together. However, welding aluminum requires special procedures and techniques, due to its high heat conductivity and low melting point. Therefore, only qualified welders with extensive knowledge and experience in aluminum welding should perform these repairs. Another method is using a filler material such as epoxy or aluminum powder to fill the voids and pores in the forging. This method is suitable for minor defects and is more straightforward than welding.

When it comes to modifying large aluminum forgings, there are several methods available. The most common method is to re-forging the component, which is also known as "remedial forging." This process involves reheating the forging and re-forging it to correct the defects that were present in the original forging. This method can restore the mechanical properties and dimensions of the original forging, but it may also lead to some distortion or shrinkage of the final product. Therefore, it is essential to balance the advantages and disadvantages of this method before deciding whether to use it.

Another method of modifying large aluminum forgings is through machining. This method involves removing excess material from the forging to correct dimensional inaccuracies, surface defects, or to modify the shape of the component. Machining is often used in conjunction with other repair methods, such as welding or filler material application, to create a fully functional component.

In recent years, new technologies have emerged to help repair and modify large aluminum forgings more efficiently and effectively. For example, laser cladding technology can be used to repair damaged or worn surfaces on the forging by applying a layer of aluminum powder to the surface, which is melted by a laser beam as it is added. This process can create a fully dense, defect-free coating that is similar in composition and properties to the original aluminum material. Another technology that has been developed is friction stir welding, which uses a rotating tool to join two pieces of aluminum without melting them. This process can create high-quality, defect-free welds that are stronger than traditional welding methods.

In conclusion, large aluminum forgings are essential components of many industrial and manufacturing applications. However, they may experience defects and faults during the production process, which require repair and modification. Several methods are available for these tasks, including welding, filler material application, remedial forging, machining, laser cladding, and friction stir welding. Each method has its own advantages and disadvantages, and the choice of a particular method should be based on the specific requirements of the component and the capabilities of the repair and modification team. By utilizing these methods effectively, manufacturers can ensure that their large aluminum forgings are of the highest quality and function correctly throughout their service life.

- Article title

- Article summary

- Article content

- Multi Field Search

Latest News

- What are the strength classes of aluminum extrusion products?

- The prominent advantages of extruded aluminum tubes in the application scenarios of the construction industry (三)

- The prominent advantages of extruded aluminum tubes in the application scenarios of the construction industry (二)

- The prominent advantages of extruded aluminum tubes in the application scenarios of the construction industry (一)

- prominent advantages of extruded aluminum tubes in automotive industry application scenarios(三)

- prominent advantages of extruded aluminum tubes in automotive industry application scenarios(二)