The Benefits of Using Aluminum Alloy Forging Rings in Heavy Equipment Manufacturing

Views: 0 Author: Site Editor Publish Time: 2024-04-26 Origin: Site

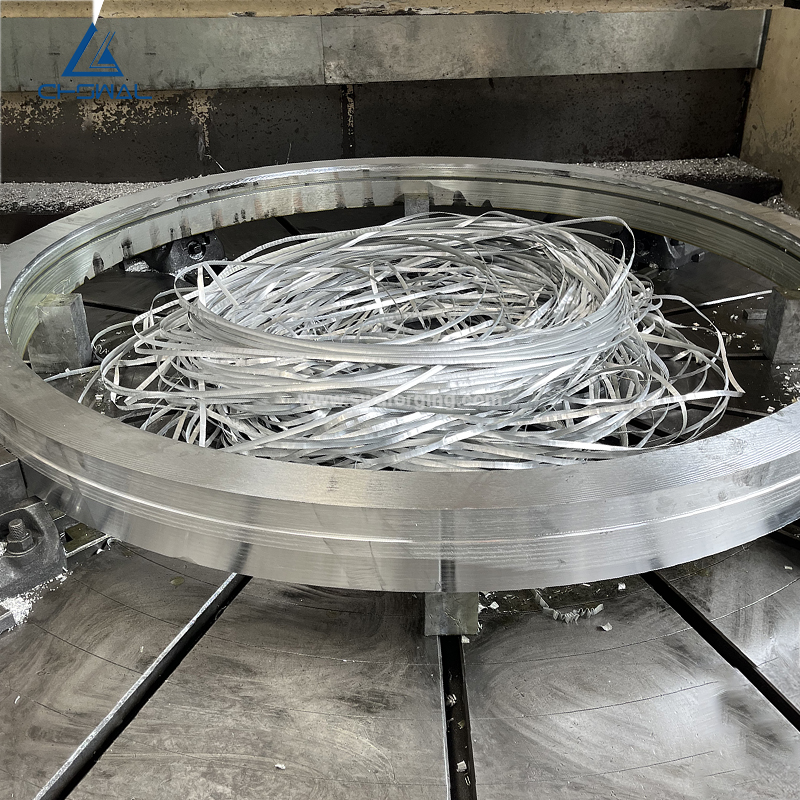

The use of aluminum alloy ring forging in heavy equipment manufacturing has become increasingly popular in recent years. Aluminum alloy is known for its strength, light weight, and resistance to corrosion, which makes it perfect for heavy equipment that requires durable and long-lasting components. In this article, we will explore the benefits of using aluminum alloy ring forging in heavy equipment manufacturing.

Advantages of Aluminum Alloy Ring Forging

1. Higher Strength-to-Weight Ratio

One of the biggest benefits of using aluminum alloy ring forging in heavy equipment manufacturing is its high strength-to-weight ratio. Aluminum alloy is approximately one-third the weight of steel but has almost the same strength. As a result, aluminum alloy ring forging can reduce the overall weight of the heavy equipment without compromising durability and functionality. This lightweight design characteristic can also result in reduced fuel consumption, making heavy equipment more environmentally friendly and cost-effective.

One of the biggest benefits of using aluminum alloy ring forging in heavy equipment manufacturing is its high strength-to-weight ratio. Aluminum alloy is approximately one-third the weight of steel but has almost the same strength. As a result, aluminum alloy ring forging can reduce the overall weight of the heavy equipment without compromising durability and functionality. This lightweight design characteristic can also result in reduced fuel consumption, making heavy equipment more environmentally friendly and cost-effective.

2. Corrosion Resistance

Aluminum alloy ring forging is highly resistant to corrosion, meaning it can withstand exposure to harsh environments. Heavy equipment often operates in challenging conditions, ranging from extreme temperatures to corrosive liquids and gases. Using aluminum alloy ring forgings can ensure that heavy equipment lasts longer and has a lower maintenance cost.

3. Increased Durability

Aluminum alloy ring forging has excellent strength and durability due to its forging process. Forging involves the application of high pressure to deform a metal and form the desired shape. This process can improve the material's chemical and mechanical properties and make it more resistant to fatigue and wear. The result is rings that are long-lasting and capable of withstanding heavy loads, high temperatures, and other stressful conditions.

4. Versatility

Aluminum alloy ring forging's versatility makes it suitable for a wide range of applications and industries. It can be used in heavy equipment, aerospace, automotive, and military industries, among others. Aluminum alloy ring forging can also be customized to match specific requirements, such as shape, size, and strength. This versatile characteristic makes it a popular and cost-effective choice for heavy equipment manufacturers.

Conclusion

The use of aluminum alloy ring forging in heavy equipment manufacturing offers a range of benefits. Its lightweight design, high strength-to-weight ratio, excellent corrosion resistance, and increased durability make it an ideal material for heavy equipment. The versatility of aluminum alloy ring forging also offers a cost-effective and customizable solution for heavy equipment manufacturers. As such, it is a necessity in the modern heavy equipment manufacturing industry.

- Article title

- Article summary

- Article content

- Multi Field Search

Latest News

- What is Extruded Aluminum Pipe/Tube?

- What are the strength classes of aluminum extrusion products?

- The prominent advantages of extruded aluminum tubes in the application scenarios of the construction industry (三)

- The prominent advantages of extruded aluminum tubes in the application scenarios of the construction industry (二)

- The prominent advantages of extruded aluminum tubes in the application scenarios of the construction industry (一)

- prominent advantages of extruded aluminum tubes in automotive industry application scenarios(三)