Articles

- Aluminium Alloy Use In The Aerospace Defense

2022-08-17

The aircraft and aerospace industries have long relied upon aluminum alloys. After the aluminum (aluminum-copper) alloys, the most important aircraft material in the future will be aluminum-lithium alloys. With aluminum-lithium alloys, it is possible to reduce planes by 15%.The importance and usage Read More - What are the advantages of aluminum alloys used in the automotive field?

2022-08-05

In recent years, aluminum alloys have been widely used in the automotive field. With the vigorous promotion and application of sustainable development strategies, automotive lightweighting has become the trend of automotive progress. In the process of lightweighting of automobiles, aluminum alloy ma Read More - How about the performance of forged aluminum 7075

2022-08-05

How about the performance of forged aluminum 70757075 forged aluminum plate is a cold-treated forged alloy with high strength and hardness, far superior to mild steel. 7075 aluminum plate is one of the strongest commercial alloys, with ordinary corrosion resistance, good mechanical properties and an Read More - Is the heat treatment process of large forgings complicated?

2022-07-28

Usually, the heat treatment of large forgings is combined with the cooling of forgings, due to the large section size and complex production process of large forgings. During the heat treatment process, some forgings are prone to white spot defects due to the uneven structure and properties of the f Read More - How to improve the quality of gear forgings

2022-07-26

In addition to the hardness value required to improve the quality of gear forgings, other mechanical performance indicators must also be specified:1. Reasonable combination of strength and toughness. Usually the strength and toughness of steel materials are trade-offs. For structural forgings, the p Read More - What is the processing flow of cake forgings?

2022-07-20

Cake satin parts are also called short shaft forgings. The processing process is divided into three types according to the difficulty of forming: ordinary forgings, high-hub deep-hole forgings and high-rib thin-walled complex forgings. The processing process is generally upsetting. , Upsetting to ga Read More - What should be paid attention to in the forging process of heavy forgings

2022-07-20

A heavy forging is when a large piece of metal is stressed and shaped to serve its purpose. This force is typically achieved through the use of a hammer or pressure. The forging process builds a refined grain structure and improves the physical properties of the metal. In real-world use of the compo Read More - How to improve crack marks in cylinder forgings

2022-07-14

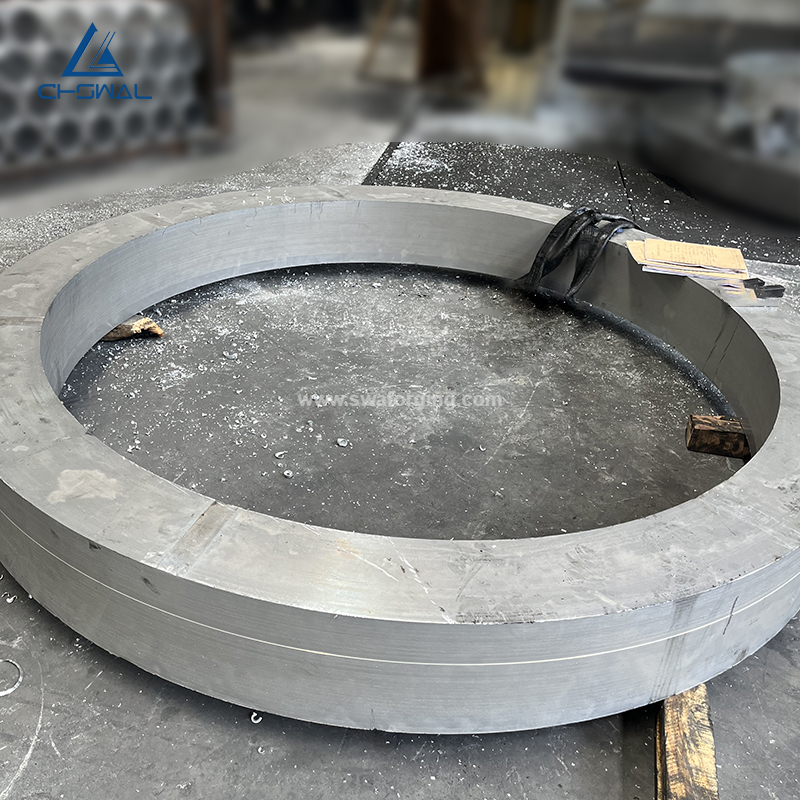

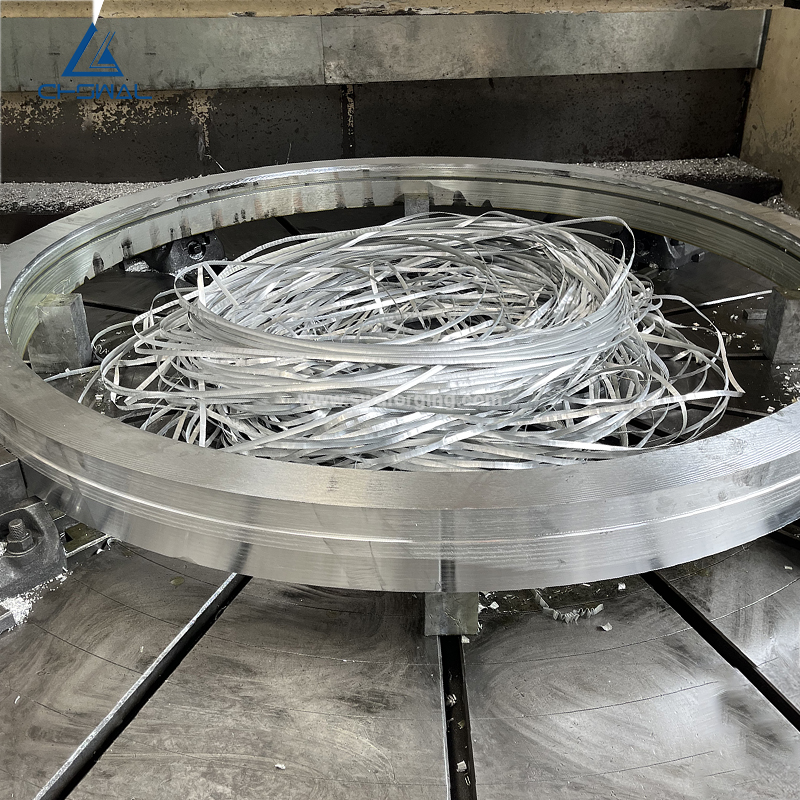

The physical properties and mechanical properties of alumina and titanium oxide brittle inclusions in the riser area of cylinder forgings are quite different from those of the matrix. During the stress deformation process, the brittle inclusions cannot deform with the metal correspondingly, and stre Read More - Features of ring forging

2022-07-14

Ring-rolling processing of ring forgings is to use ring rolling machines (also known as ring rolling machines, ring rolling mills, and hole reamers) to produce continuous local plastic deformation of the rings, thereby realizing the reduction of wall thickness, expansion of diameter, and plastic pro Read More - Ring forgings show a good development trend

2022-07-07

Ring-rolling processing of ring forgings is to use ring rolling machines (also known as ring rolling machines, ring rolling mills, and hole reamers) to produce continuous local plastic deformation of the rings, thereby realizing the reduction of wall thickness, expansion of diameter, and plastic pro Read More - What are the technical requirements of forged aluminum for raw materials?

2022-07-07

The selection of quality raw materials is a prerequisite for ensuring the quality of forgings. The main links that determine the quality of raw materials are smelting, ingot casting and semi-finished product processing. Read More - What are the types of corrosion in aluminum alloy forging?

2022-06-29

Aluminum alloy forging will also be corroded after long-term use, and the common manifestations are pitting corrosion, galvanic corrosion, crevice corrosion, intergranular corrosion, filiform corrosion, etc.1. Pitting corrosion is a very localized form of corrosion that produces needle-like, spot-li Read More