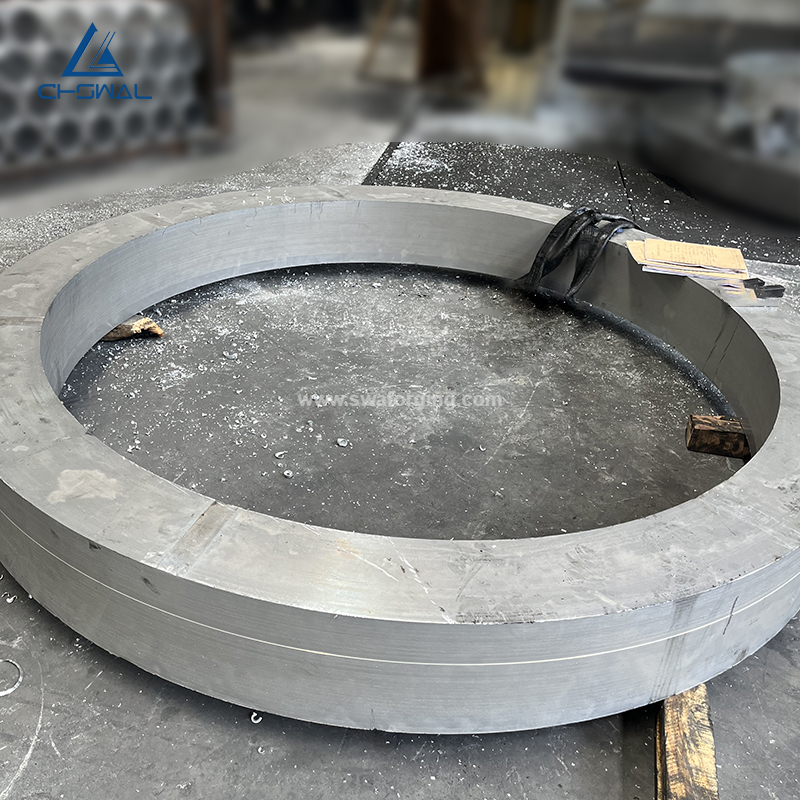

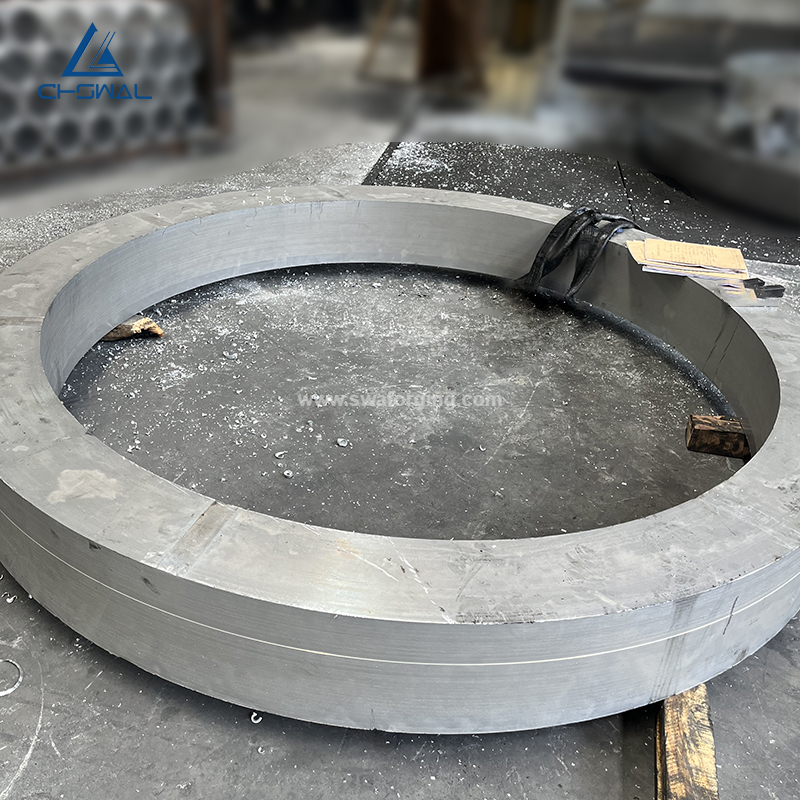

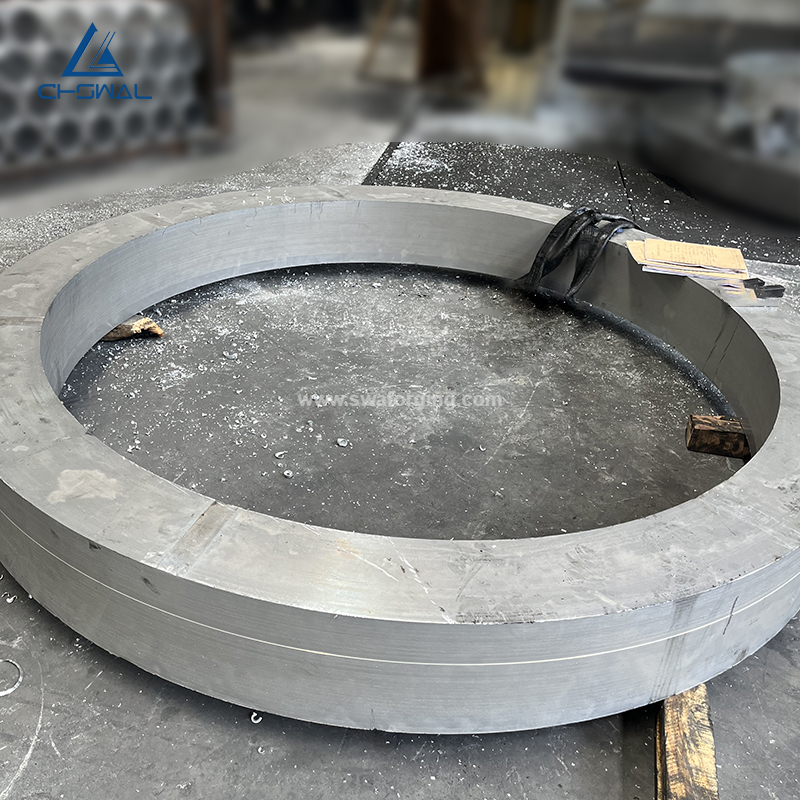

7075 rolled aluminium forged rings are high-quality rings made from aluminium alloy 7075. This type of alloy is known for its strength, durability, and corrosion resistance, making it an excellent choice for many industries such as aircraft, aerospace, and defense.

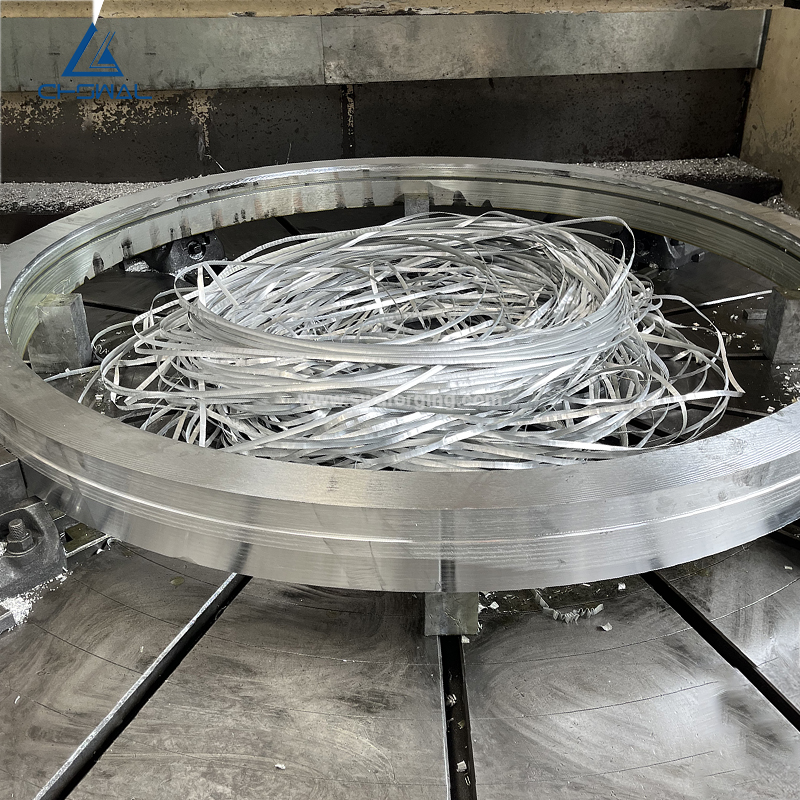

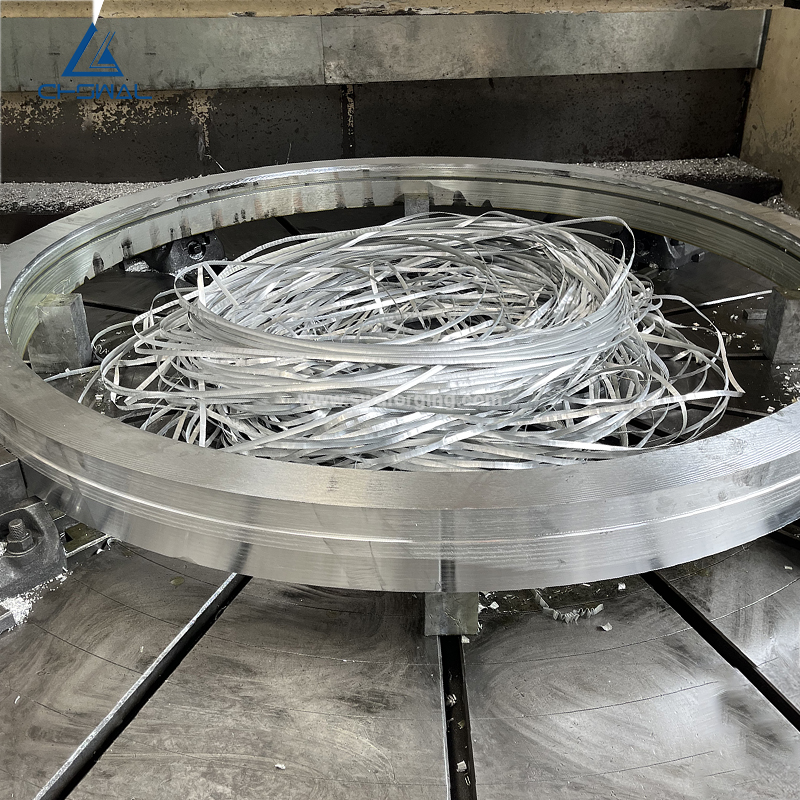

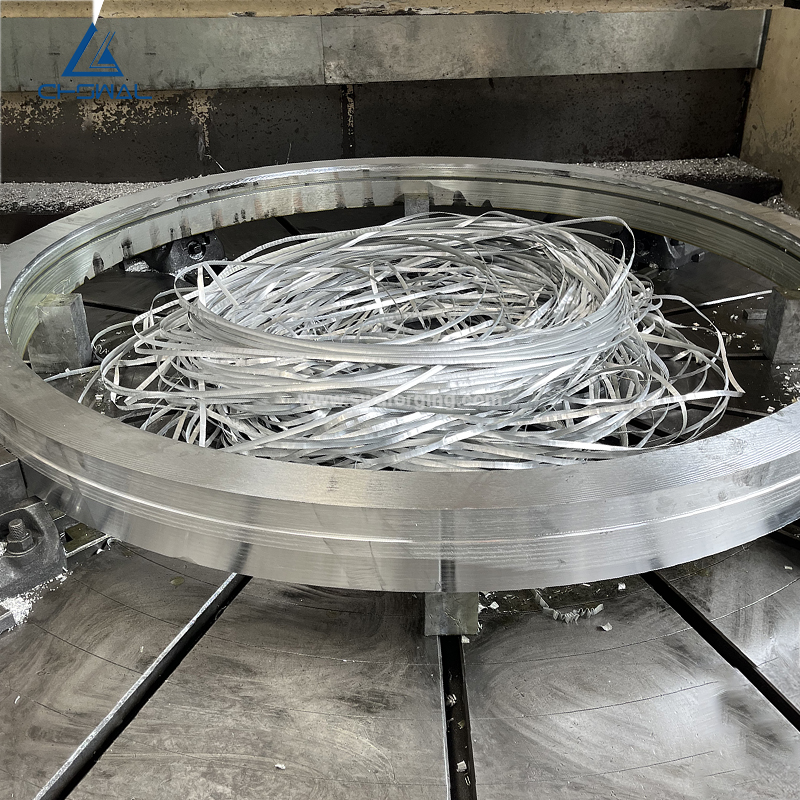

These forged rings are created using a process called hot forging, where the metal is heated to high temperatures to make it more malleable, then shaped into the desired form using pressure and force exerted by dies. This process results in a much stronger and more durable product compared to traditional casting methods.

Product parameters

Forging Tolerance: +/-0.01mm

Standard: ASTM, ASME, JIS, GB,etc.

Molding Style: Forging

Material: aluminum alloy

Outer diameter of quenching parts ≤ 2500mm,

Outer diameter of non-quenching parts ≤ 4000mm,

Height ≤ 500mm

Chemical composition (GB/T 3190-2008)

Silicon Si: 0.40

Iron Fe: 0.50

Copper Cu: 1.2-2.0

Manganese Mn: 0.30

Magnesium Mg: 2.1-2.9

Chromium Cr: 0.18-0.28

Zinc Zn: 5.1-6.1

Titanium Ti: 0.20

Aluminum Al: margin

Other: single: 0.05 Total: 0.15

Benefits of 7075 rolled aluminium forged rings

One of the benefits of 7075 rolled aluminium forged rings is their high strength-to-weight ratio. This means that they are incredibly strong and durable, while still remaining lightweight, making them ideal for use in applications where weight is a critical factor.

These rings are also highly resistant to corrosion, which is important in industries such as aerospace and defense where exposure to harsh weather conditions and chemicals is common.

Overall, 7075 rolled aluminium forged rings are a top-quality product that offers strength, durability, and corrosion resistance, making them an excellent choice for a wide range of industries.

Applications of 7075 rolled aluminium forged rings

7075 rolled aluminium forged rings are high-strength and lightweight components that have wide applications in various industries. These rings are produced using advanced forging technologies that make them highly resistant to fatigue and wear, ensuring excellent performance for extended periods.

One of the significant applications of 7075 rolled aluminium forged rings is in the aerospace industry. These rings are used in the production of aircraft parts such as engine mounts, fuselage frames, and landing gears due to their exceptional strength and durability. Additionally, these rings are also highly sought after in the automotive and defense industries, where high-performance and lightweight components are crucial.

7075 rolled aluminium forged rings are also used in the manufacturing of heavy equipment such as excavators, cranes, and bulldozers. The high strength-to-weight ratio of these rings makes them ideal for use in heavy equipment applications, where maximum strength is required without adding excessive weight.

The marine and offshore industries also rely heavily on 7075 rolled aluminium forged rings. These rings are used in the construction of offshore platforms, oil rigs, and ships due to their excellent corrosion and wear resistance.

In conclusion, 7075 rolled aluminium forged rings have numerous applications across a variety of industries, from aerospace and automotive to marine and offshore. They are high-strength, lightweight and durable components that ensure optimal performance and longevity